Nitrogen generation is a crucial process in various industrial sectors, providing high-purity nitrogen for applications ranging from manufacturing to food preservation. Understanding the components, like air compressors and nitrogen generators, and their maintenance is essential for efficient operation.

On-site nitrogen generation offers numerous benefits compared to traditional nitrogen supply methods such as cylinders or bulk liquid deliveries. By producing nitrogen directly at the point of use, businesses can reduce costs, eliminate the need for frequent deliveries, and ensure a consistent supply of high-purity nitrogen. Additionally, on-site generation allows for greater control over nitrogen purity and flow rate, enabling businesses to adapt to changing demands and optimize their processes.

Selecting the Right Air Compressor

Air Compressor for Nitrogen Generators

The air compressor is a critical component in nitrogen generation. It provides the compressed air that the nitrogen generator uses to produce nitrogen.

The selection of an air compressor should be based on the nitrogen generator's requirements, including flow rate, pressure, and purity level.

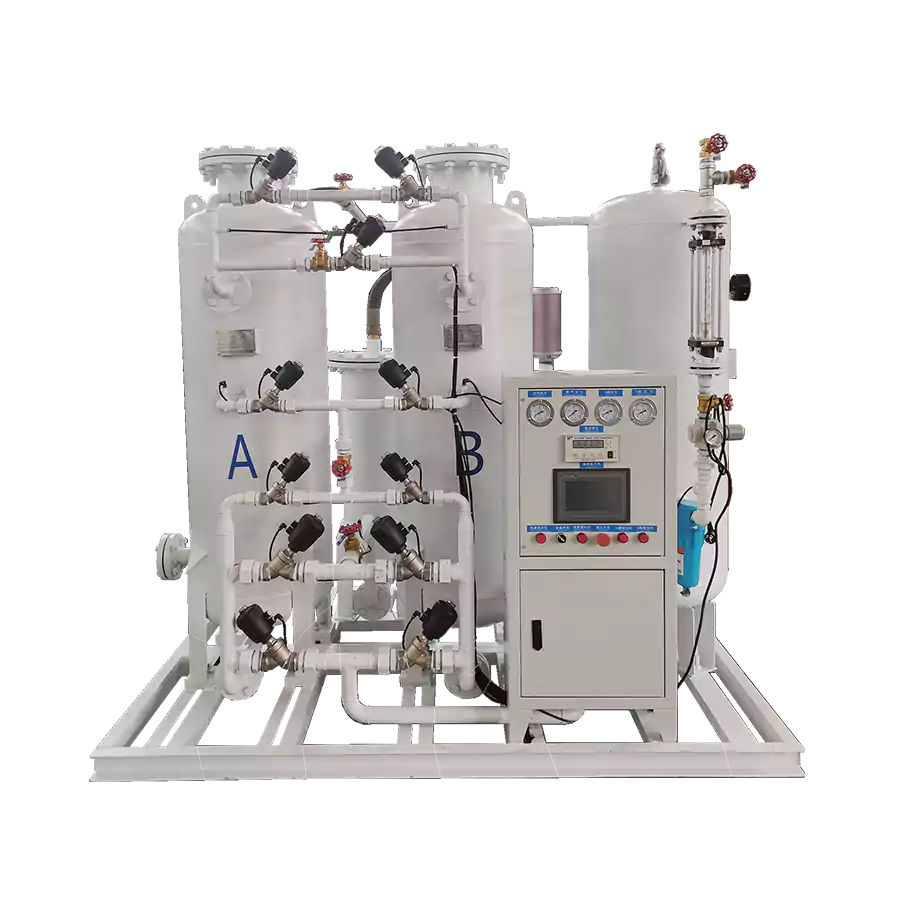

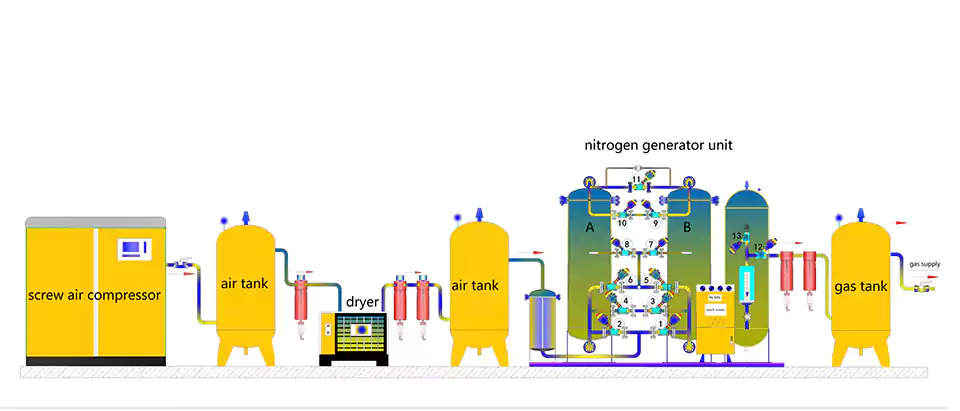

Using high-quality carbon molecular sieve (CMS) as the adsorbent, nitrogen gas is separated and extracted from pure, dry compressed air through pressure swing adsorption. In the adsorption tower, the diffusion rate of oxygen in the micropores of the carbon molecular sieve is much higher than that of nitrogen and is adsorbed.

Nitrogen is enriched in the gas phase to form nitrogen as a finished product; when the pressure is reduced to normal pressure in the regeneration tower, the adsorption capacity of the carbon molecular sieve for oxygen drops sharply. The adsorbed oxygen and other impurities are desorbed to realize regeneration.

Generally, two towers are connected in parallel, and the pressure adsorption and decompression desorption are alternately controlled by PLC to continuously and stably produce high-purity nitrogen.

When selecting an air compressor for a nitrogen generator, it's essential to consider factors such as:

Capacity: The air compressor must be able to provide sufficient compressed air flow to meet the nitrogen generator's requirements. This is typically measured in cubic feet per minute (CFM) or liters per minute (L/min).

Pressure: The air compressor should deliver compressed air at the appropriate pressure for the nitrogen generator. This is usually between 100 and 150 PSI (7-10 bar) for most nitrogen generation technologies.

Air Quality: The compressed air supplied to the nitrogen generator must be clean, dry, and free of contaminants. This may require additional air treatment components, such as filters, dryers, and oil separators, to ensure the compressed air meets the necessary quality standards.

Energy Efficiency: Choosing an energy-efficient air compressor can significantly reduce operating costs over the life of the nitrogen generation system. Look for compressors with variable speed drives, high-efficiency motors, and advanced control systems to optimize energy consumption.

Reliability: A reliable air compressor is crucial to ensure consistent nitrogen production and minimize downtime. Consider factors such as the manufacturer's reputation, warranty, and service support when selecting an air compressor.

Key Factors in Air Compressor Selection

When selecting an air compressor for a PSA nitrogen generator, consider the required air flow and pressure to ensure efficient nitrogen generation. Also, the quality of compressed air affects the nitrogen purity; hence, choosing a compressor that can provide clean, dry air is vital.

The relation of capacity and purity of the nitrogen generator and air flow of the air compressor is as follows:

- For 99% N2 purity, the Air:N2 ratio is 3:1

- For 99.9% N2 purity, the Air:N2 ratio is 4:1

- For 99.99% N2 purity, the Air:N2 ratio is 5:1

- For 99.999% N2 purity, the Air:N2 ratio is 7:1

For example, in the oil field industry, if a customer needs 99% N2 at 3m3/min and 8 bar, we need to match compressed air at 9 m3/min and 10 bar, considering the pressure drop in actual operation.

Other key factors to consider when selecting an air compressor for a nitrogen generator include:

Compressor Type: Different types of air compressors, such as rotary screw, reciprocating, or centrifugal compressors, have varying characteristics in terms of flow rate, pressure, and efficiency. Choose the compressor type that best suits your nitrogen generation requirements and application.

Maintenance Requirements: Consider the maintenance needs of the air compressor, including regular service intervals, part replacements, and ease of access for maintenance tasks. Choosing a compressor with lower maintenance requirements can help reduce downtime and operating costs.

Integration with Nitrogen Generator: Ensure that the selected air compressor is compatible with the nitrogen generator and can be easily integrated into the overall system. This may involve considerations such as piping, electrical connections, and control systems.

Footprint and Installation: Consider the physical size of the air compressor and the space available for installation. Compact compressors may be preferred for applications with limited floor space, while larger compressors may be suitable for outdoor installations or dedicated compressor rooms.

Future Expansion: If your nitrogen demand is expected to grow in the future, choose an air compressor that can accommodate increased flow rates or consider a modular system that allows for easy expansion.

By carefully evaluating these factors and working with experienced compressed air and nitrogen generation professionals, you can select an air compressor that optimally meets your nitrogen generation requirements, ensuring reliable and efficient operation.

Nitrogen Generation Technology

PSA Nitrogen Generation

Pressure Swing Adsorption (PSA) is a popular technology for on-site nitrogen generation. It separates nitrogen and oxygen in the air through molecular sieves under pressure differences.

Understanding the working principle of PSA nitrogen generators helps in optimizing the process for increased nitrogen purity.

A PSA nitrogen generator isolates nitrogen, and the other gases in the compressed air stream (oxygen, CO2, and water vapor) are adsorbed, leaving behind essentially pure nitrogen. PSA nitrogen generator technology is a simple, reliable, and cost-effective approach to nitrogen generation that enables continuous, high-capacity nitrogen flow at the desired level of purity.

The PSA process involves two main steps:

Adsorption: Compressed air enters a vessel containing a carbon molecular sieve (CMS) material. The CMS has a high affinity for oxygen, carbon dioxide, and water vapor, which are adsorbed onto its surface, while nitrogen passes through the sieve.

Regeneration: Once the CMS is saturated with adsorbed gases, the vessel is depressurized, and a small portion of the nitrogen product is used to purge the CMS, releasing the adsorbed gases and regenerating the sieve for the next adsorption cycle.

PSA nitrogen generators typically use a dual-bed system, with one vessel in the adsorption phase while the other is in the regeneration phase. This allows for continuous nitrogen production without interruption. The purity of the nitrogen produced by a PSA system can range from 95% to 99.999%, depending on the specific design and operating conditions.

Advantages of PSA nitrogen generation include:

- High nitrogen purity levels (up to 99.999%)

- Reliable and consistent nitrogen supply

- Low operating costs compared to delivered nitrogen

- Compact footprint and easy installation

- Fully automated operation with minimal maintenance requirements

Membrane Nitrogen Generation

Membrane technology filters nitrogen from other gases using a selective permeable membrane. It's suitable for applications requiring lower nitrogen purity compared to PSA.

While higher purity levels are used in industries like food processing, for lower purity needs, often generating nitrogen using membrane technology is preferred.

Membrane nitrogen generators use hollow fiber membranes to separate nitrogen from compressed air. The membranes are composed of polymeric materials that allow smaller gas molecules, such as oxygen and water vapor, to permeate through the membrane walls faster than larger molecules like nitrogen.

The membrane separation process involves the following steps:

Compression: Compressed air is introduced into the membrane module at a high pressure, typically between 100 and 150 PSI (7-10 bar).

Separation: As the compressed air passes through the hollow fiber membranes, oxygen, water vapor, and other smaller molecules permeate through the membrane walls, while nitrogen is retained on the high-pressure side of the membrane.

Nitrogen Collection: The nitrogen-rich gas is collected from the high-pressure side of the membrane and is ready for use in the application.

Membrane nitrogen generators are capable of producing nitrogen with purities ranging from 95% to 99.5%, depending on the system design and operating conditions. They are generally more compact and have lower capital costs compared to PSA systems, making them a popular choice for applications with lower purity requirements or space constraints.

Advantages of membrane nitrogen generation include:

- Lower capital cost compared to PSA systems

- Compact design and easy installation

- Simple operation with few moving parts

- Low maintenance requirements

- Quick start-up and response to changes in nitrogen demand

However, membrane systems have some limitations, such as lower nitrogen purity capabilities compared to PSA and a higher sensitivity to fluctuations in compressed air quality and pressure. The choice between PSA and membrane technology ultimately depends on the specific application requirements, purity needs, and economic considerations.

Maintenance and Cost Optimization

Regular Nitrogen Generator Maintenance

Regular maintenance of a nitrogen generator is essential for operational efficiency and longevity. This includes checking the molecular sieves, valves, and filters, ensuring the system's continuous and reliable performance.

A well-maintained nitrogen generator ensures consistent nitrogen purity, reduces the risk of unplanned downtime, and extends the life of the equipment. Regular maintenance tasks for nitrogen generators typically include:

Filter Replacement: Inlet air filters, coalescing filters, and particulate filters should be replaced at regular intervals as specified by the manufacturer. This ensures that the compressed air entering the nitrogen generator is clean, dry, and free of contaminants.

Valve Inspection: Check and maintain the valves in the nitrogen generator, including inlet, outlet, and purge valves. Ensure that they are functioning properly and replace any worn or damaged components.

Molecular Sieve Replacement: For PSA nitrogen generators, the carbon molecular sieve (CMS) material will need to be replaced after a certain number of operating hours or years, as specified by the manufacturer. This is necessary to maintain the system's nitrogen purity and efficiency.

Leak Detection: Regularly inspect the nitrogen generator and associated piping for leaks. Leaks can lead to reduced nitrogen purity, increased energy consumption, and potential safety hazards.

Instrumentation Calibration: Calibrate pressure gauges, flow meters, and other instrumentation to ensure accurate monitoring and control of the nitrogen generation process.

Performance Monitoring: Keep track of the nitrogen generator's performance, including nitrogen purity, flow rate, and energy consumption. This can help identify any potential issues and allow for proactive maintenance.

Establishing a regular maintenance schedule and following the manufacturer's recommended maintenance procedures can help optimize the performance and longevity of your nitrogen generator. It's also essential to have trained personnel or a reliable service provider to carry out maintenance tasks and address any issues promptly.

Managing Nitrogen Generation Costs

The cost of nitrogen generation includes equipment, operation, and maintenance expenses. To manage costs effectively, consider the total cost of ownership, including energy consumption, maintenance requirements, and potential downtime. To manage costs effectively, consider the total cost of ownership, including energy consumption, maintenance, and potential downtime.

Nitrogen generation costs can be broken down into three main categories:

Capital Costs: This includes the initial investment in the nitrogen generator, air compressor, and associated equipment, such as filters, dryers, and storage tanks. Capital costs can vary significantly depending on the technology (PSA or membrane), system size, and specific features.

Operating Costs: The primary operating cost for nitrogen generation is energy consumption, which is mainly driven by the air compressor. Other operating costs may include consumables (filters, molecular sieves) and regular maintenance expenses.

Maintenance Costs: Regular maintenance is essential to ensure the reliable and efficient operation of the nitrogen generation system. Maintenance costs can include labor, spare parts, and consumables.

To manage nitrogen generation costs effectively, consider the following strategies:

Optimize System Design: Work with a knowledgeable nitrogen generation equipment provider to design a system that meets your specific requirements while minimizing capital and operating costs. This may involve selecting the most appropriate technology, sizing the equipment correctly, and incorporating energy-efficient components.

Implement Energy Management Strategies: Optimize the air compressor's operation to minimize energy consumption. This can include using variable speed drives, implementing proper control strategies, and ensuring that the compressed air system is properly sized and maintained.

Preventive Maintenance: Implementing a regular preventive maintenance program can help reduce the risk of unplanned downtime, extend equipment life, and minimize repair costs. This includes tasks such as regular filter changes, valve inspections, and leak detection.

Monitor Performance: Regularly monitor the performance of your nitrogen generation system, including nitrogen purity, flow rate, and energy consumption. This can help identify potential issues early and allow for proactive maintenance, reducing the risk of costly downtime.

Consider Total Cost of Ownership: When evaluating nitrogen generation options, consider the total cost of ownership over the life of the equipment, rather than just the initial capital cost. This includes factors such as energy consumption, maintenance costs, and the potential impact of downtime on your production process.

Optimize Nitrogen Usage: Assess your nitrogen requirements carefully and implement measures to minimize waste and optimize usage. This can include using nitrogen-efficient processes, implementing proper storage and distribution systems, and regularly reviewing your nitrogen demand to ensure that your generation capacity is appropriately sized.

By taking a comprehensive approach to managing nitrogen generation costs, including optimizing system design, implementing energy management strategies, and focusing on preventive maintenance, you can minimize the total cost of ownership while ensuring a reliable and efficient supply of high-purity nitrogen for your application.

Frequently Asked Questions

Q: How do I choose the right air compressor for a nitrogen generator? A: Consider the nitrogen generator's air flow and pressure requirements, ensuring the compressor can meet these needs efficiently. Learn more about choosing a suitable air compressor.

Q: What are the main types of nitrogen generation technologies? A: The two main technologies are PSA, which uses molecular sieves to separate gases, and membrane, which uses a selective permeable membrane.

Q: How often should nitrogen generators be maintained? A: Regular maintenance schedules vary based on usage and manufacturer recommendations. However, periodic checks and annual servicing are generally advised.

Q: What purity levels can be achieved with on-site nitrogen generation? A: PSA nitrogen generators can produce nitrogen with purities up to 99.999%, while membrane systems typically achieve purities between 95% and 99.5%.

Q: How can I optimize the cost of nitrogen generation? A: To optimize costs, consider factors such as system design, energy management, preventive maintenance, performance monitoring, and total cost of ownership. Implementing strategies to minimize energy consumption, reduce downtime, and extend equipment life can help manage costs effectively.

Q: What are the benefits of on-site nitrogen generation compared to delivered nitrogen? A: On-site nitrogen generation offers several benefits, including lower long-term costs, increased reliability, flexibility to meet changing demands, and reduced environmental impact by eliminating the need for transportation and storage of nitrogen cylinders or bulk liquid nitrogen.

By understanding the key aspects of on-site nitrogen generation, including air compressor selection, nitrogen generation technologies, maintenance requirements, and cost optimization strategies, you can make informed decisions when implementing a nitrogen generation system for your application. Consult with experienced compressed air and nitrogen generation professionals to design a system that meets your specific requirements while optimizing performance and cost-effectiveness.

Meta description: Explore the essentials of on-site nitrogen generation, including air compressor selection, PSA and membrane nitrogen generation technologies, and tips for efficient maintenance and cost management.