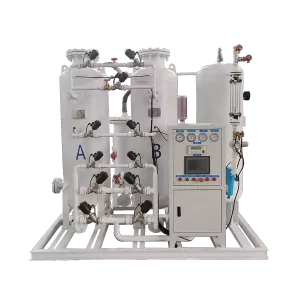

Home » Products » PSA Nitrogen Generator » Elaire PSA Nitrogen Generator

Pressure Swing Adsorption (PSA) technology separates nitrogen from compressed air by adsorbing the oxygen in the air using Carbon Molecular Sieve material. Because this adsorbent will become saturated with O₂, the generator consists of two vessels. While one vessel produces nitrogen, the other regenerates its saturated CMS, rotating as needed.

Advantages of ELN series PSA nitrogen generator:

Key components of the Elaire PSA Nitrogen Generator include:

| Model | N2 Capacity | Inlet | Outlet | Tank Volume | L*W |

|---|---|---|---|---|---|

| Purity: 97% | Nm³/h | mm | mm | m³ | mm |

| ELN10 | 10 | 15 | 15 | 0.1 | 1330×750 |

| ELN20 | 20 | 25 | 15 | 0.2 | 1500×800 |

| ELN30 | 30 | 25 | 15 | 0.2 | 1650×850 |

| ELN40 | 40 | 25 | 25 | 0.2 | 1800×1000 |

| ELN50 | 50 | 32 | 25 | 0.3 | 2000×1050 |

| ELN60 | 60 | 32 | 25 | 0.3 | 2100×1100 |

| ELN80 | 80 | 40 | 25 | 0.6 | 2250×1200 |

| ELN100 | 100 | 40 | 32 | 0.6 | 2400×1300 |

| ELN150 | 150 | 50 | 32 | 1.0 | 2900×1650 |

| ELN200 | 200 | 50 | 32 | 1.0 | 3050×1800 |

| ELN300 | 300 | 65 | 40 | 1.5 | 3300×2050 |

| ELN400 | 400 | 65 | 40 | 2.0 | 3450×2150 |

| ELN500 | 500 | 80 | 50 | 2.0 | 3800×2300 |

| ELN 600 | 600 | 80 | 50 | 2.0 | 4000×2400 |

| ELN800 | 800 | 100 | 65 | 3.0 | 4250×2450 |

| ELN1000 | 1000 | 100 | 65 | 4.0 | 4450×2600 |

| ELN1500 | 1500 | 125 | 80 | 5.0 | 4700×2800 |

| ELN2000 | 2000 | 150 | 100 | 6.0 | 5000×3000 |

| ELN2500 | 2500 | 200 | 100 | 8.0 | 5250×3250 |

| Model | N2 Capacity | Inlet | Outlet | Tank Volume | L*W |

|---|---|---|---|---|---|

| Purity: 99% | Nm³/h | mm | mm | m³ | mm |

| ELN10 | 10 | 15 | 15 | 0.1 | 1430×800 |

| ELN20 | 20 | 25 | 15 | 0.2 | 1650×850 |

| ELN30 | 30 | 25 | 15 | 0.2 | 1750×900 |

| ELN40 | 40 | 25 | 25 | 0.3 | 1900×1050 |

| ELN50 | 50 | 32 | 25 | 0.3 | 2150×1100 |

| ELN60 | 60 | 32 | 25 | 0.6 | 2200×1160 |

| ELN80 | 80 | 40 | 25 | 0.6 | 2350×1300 |

| ELN100 | 100 | 40 | 32 | 0.6 | 2600×1350 |

| ELN150 | 150 | 50 | 32 | 1.0 | 3200×1450 |

| ELN200 | 200 | 50 | 32 | 1.0 | 3360×1600 |

| ELN300 | 300 | 60 | 40 | 1.5 | 3600×2250 |

| ELN400 | 400 | 60 | 40 | 2.0 | 3750×2350 |

| ELN500 | 500 | 80 | 50 | 2.0 | 4100×2380 |

| ELN600 | 600 | 80 | 50 | 2.0 | 4250×2450 |

| ELN800 | 800 | 100 | 65 | 3.0 | 4450×2550 |

| ELN1000 | 1000 | 100 | 65 | 4.0 | 5000×2750 |

| ELN1500 | 1500 | 125 | 80 | 5.0 | 5100×3000 |

| ELN2000 | 2000 | 150 | 100 | 6.0 | 5300×3250 |

| ELN2500 | 2500 | 200 | 100 | 8.0 | 5650×3500 |

| Model | N2 Capacity | Inlet | Outlet | Tank Volume | L*W |

|---|---|---|---|---|---|

| Purity: 99.5% | Nm³/h | mm | mm | m³ | mm |

| ELN10 | 10 | 15 | 15 | 0.1 | 1450×830 |

| ELN20 | 20 | 25 | 15 | 0.2 | 1680×860 |

| ELN30 | 30 | 25 | 15 | 0.2 | 1800×920 |

| ELN40 | 40 | 25 | 25 | 0.3 | 1950×1100 |

| ELN50 | 50 | 32 | 25 | 0.3 | 2200×1200 |

| ELN60 | 60 | 32 | 25 | 0.6 | 2300×1200 |

| ELN80 | 80 | 40 | 25 | 0.6 | 2380×1300 |

| ELN100 | 100 | 40 | 32 | 0.6 | 2700×1450 |

| ELN150 | 150 | 50 | 32 | 1.0 | 3050×1550 |

| ELN200 | 200 | 50 | 32 | 1.5 | 3450×1800 |

| ELN300 | 300 | 65 | 40 | 2.0 | 3700×2050 |

| ELN400 | 400 | 65 | 40 | 2.5 | 3850×2450 |

| ELN500 | 500 | 80 | 50 | 3.0 | 4180×2550 |

| ELN600 | 600 | 80 | 50 | 3.0 | 4350×2650 |

| ELN800 | 800 | 100 | 65 | 4.0 | 4650×2750 |

| ELN1000 | 1000 | 100 | 65 | 6.0 | 5150×2850 |

| ELN1500 | 1500 | 125 | 80 | 8.0 | 5200×3200 |

| ELN2000 | 2000 | 150 | 100 | 8.0 | 5500×3500 |

| ELN2500 | 2500 | 200 | 100 | 10.0 | 5800×3800 |

| Model | N2 Capacity | Inlet | Outlet | Tank Volume | L*W |

|---|---|---|---|---|---|

| Purity: 99.9% | Nm³/h | mm | mm | m³ | mm |

| ELN10 | 10 | 15 | 15 | 0.1 | 1650×1050 |

| ELN20 | 20 | 25 | 15 | 0.2 | 1850×1100 |

| ELN30 | 30 | 25 | 15 | 0.2 | 1950×1200 |

| ELN40 | 40 | 25 | 25 | 0.3 | 2100×1250 |

| ELN50 | 50 | 32 | 25 | 0.6 | 2250×1350 |

| ELN60 | 60 | 32 | 25 | 0.6 | 2350×1380 |

| ELN80 | 80 | 40 | 25 | 1.0 | 2550×1500 |

| ELN100 | 100 | 40 | 32 | 1.0 | 2750×1650 |

| ELN150 | 150 | 50 | 32 | 1.5 | 3200×1850 |

| ELN200 | 200 | 50 | 32 | 2.0 | 3400×2100 |

| ELN300 | 300 | 65 | 40 | 2.5 | 3750×2250 |

| ELN400 | 400 | 80 | 50 | 3.0 | 4100×2550 |

| ELN500 | 500 | 86 | 50 | 4.0 | 4300×2750 |

| ELN600 | 600 | 100 | 65 | 4.0 | 4550×2750 |

| ELN800 | 800 | 125 | 65 | 5.0 | 5250×3050 |

| ELN1000 | 1000 | 125 | 65 | 6.0 | 5350×3250 |

| ELN1500 | 1500 | 150 | 80 | 8.0 | 5600×3500 |

| ELN2000 | 2000 | 150 | 100 | 10.0 | 6500×3750 |

| Model | N2 Capacity | Inlet | Outlet | Tank Volume | L*W |

|---|---|---|---|---|---|

| Purity: 99.99% | Nm³/h | mm | mm | m³ | mm |

| ELN5 | 5 | 15 | 15 | 0.2 | 1550×1050 |

| ELN10 | 10 | 15 | 15 | 0.2 | 1850×1100 |

| ELN20 | 20 | 25 | 15 | 0.3 | 2100×1250 |

| ELN30 | 30 | 32 | 25 | 0.3 | 2350×1620 |

| ELN40 | 40 | 40 | 25 | 0.6 | 2400×1550 |

| ELN50 | 50 | 40 | 25 | 0.6 | 1550×1620 |

| ELN60 | 60 | 50 | 25 | 1.0 | 2600×1750 |

| ELN80 | 80 | 50 | 25 | 1.0 | 2850×1900 |

| ELN100 | 100 | 65 | 32 | 1.5 | 2850×2050 |

| ELN150 | 150 | 65 | 40 | 2.0 | 3000×2250 |

| ELN200 | 200 | 80 | 50 | 2.0 | 3550×2300 |

| ELN300 | 300 | 100 | 50 | 3.0 | 3850×2550 |

| ELN400 | 400 | 100 | 65 | 4.0 | 4550×3250 |

| ELN500 | 500 | 125 | 65 | 5.0 | 4850×3550 |

| ELN600 | 600 | 125 | 80 | 5.0 | 5250×3650 |

| ELN800 | 800 | 150 | 80 | 6.0 | 5550×3800 |

| ELN1000 | 1000 | 150 | 100 | 6.0 | 5800×3950 |

| Model | N2 Capacity | Inlet | Outlet | Tank Volume | L*W |

|---|---|---|---|---|---|

| Purity: 99.999% | Nm³/h | mm | mm | m³ | mm |

| ELN5 | 5 | 15 | 15 | 0.2 | 1650×1150 |

| ELN10 | 10 | 25 | 15 | 0.3 | 1950×1200 |

| ELN20 | 20 | 40 | 15 | 0.6 | 2200×1350 |

| ELN30 | 30 | 40 | 25 | 1.0 | 2450×1550 |

| ELN40 | 40 | 50 | 25 | 1.0 | 2500×1650 |

| ELN50 | 50 | 50 | 25 | 1.0 | 2650×1720 |

| ELN60 | 60 | 50 | 32 | 1.5 | 2700×1850 |

| ELN80 | 80 | 65 | 40 | 1.5 | 2950×2000 |

| ELN100 | 100 | 65 | 40 | 2.0 | 2950×2150 |

| ELN150 | 150 | 80 | 50 | 2.0 | 3100×2300 |

| ELN200 | 200 | 100 | 50 | 3.0 | 3600×2400 |

| ELN300 | 300 | 125 | 50 | 4.0 | 3900×2600 |

| ELN400 | 400 | 125 | 65 | 5.0 | 4600×3200 |

| ELN500 | 500 | 125 | 65 | 5.0 | 4900×3600 |

| ELN600 | 600 | 150 | 80 | 6.0 | 5300×3700 |

Your expert in air compressors, boasting 8 years of sales mastery with a leading Chinese manufacturer. Here to guide you through the maze of air compressor selection, maintenance, and efficiency. My mission? To empower you with the knowledge and insights needed to make informed decisions. Let's embark on this journey to optimize your air systems together!