How to Determine the Air Flow and Pressure of the Air Compressor for Air Jet Looms

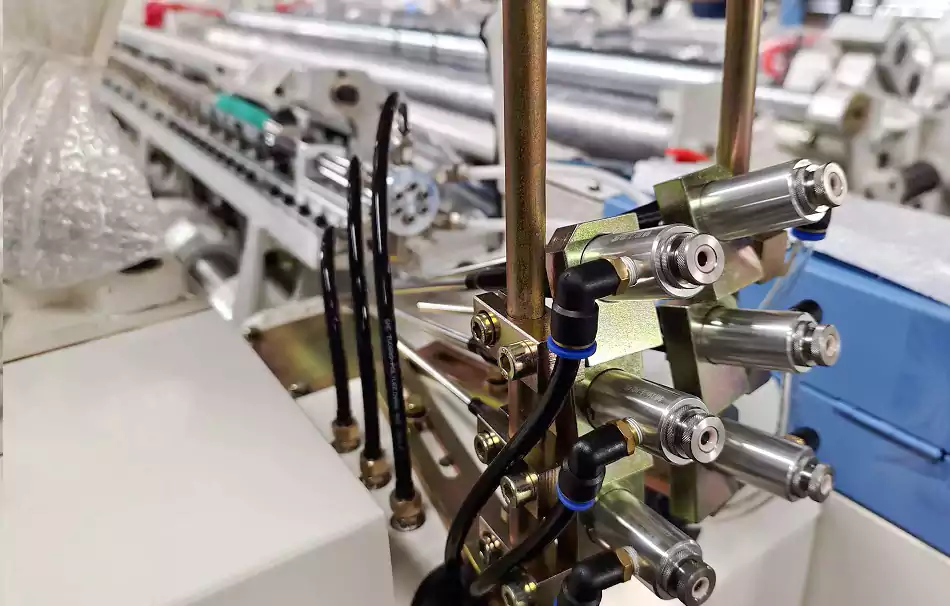

Air-jet looms are shuttleless looms which use jet air to pull the weft through the shed. The working principle is to use compressed air as the weft insertion medium, and generate frictional traction on the weft yarn to pull through the shed, and achieve the purpose of weft insertion by the air jet flow.

Step 1: Compressed Air for the Air Jet Looms

Due to the high weft insertion rate of the air jet loom, which has exceeded 3 000m/min, the loom speed is high, and the number of weft insertion per minute is large (normally 600 times/min ~ 1200 times/min); the yarn quality is light, so each time The amount of compressed air consumed by one weft insertion is small (≤0.0007m3/time ~ 0.0012m3/time); however there are many machines in the air jet loom workshop (ranging from dozens to hundreds), so it can be approximately considered that the compressed air consumption of the machine is a relatively stable value.

The more machines in the workshop and the higher the speed of the loom, the less vibration of the pressure and flow of the compressed air for the air jet loom.

Step 2: Compressed Air Consumption Calculation of Air Jet Looms

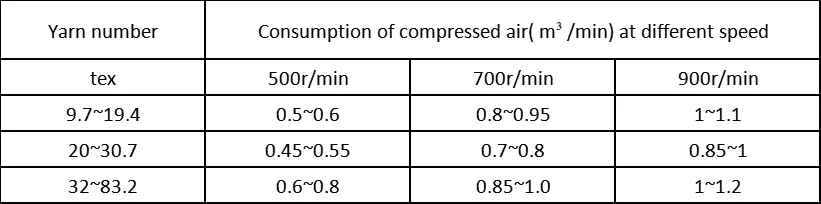

The consumption of compressed air depends on air jet loom model, fabric type and loom speed.

The type of fabric fiber, yarn number, warp and weft density, and loom speed should be provided to the supplier, and the supplier should calculate and determine.

Take nominal reed width 190 cm loom weaving pure cotton fabric as an example to calculate compressed air.

Step 3: Air Pressure of the Air Jet Looms

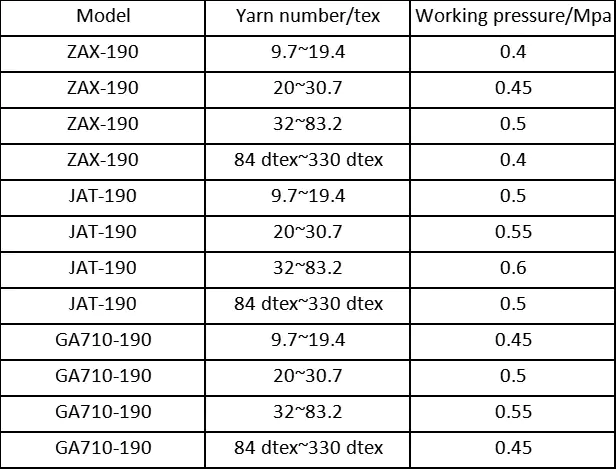

The working pressure of the air jet loom depends on the fabric specification, fiber type, loom width, loom speed and loom performance etc.. data should be provided by air jet loom supplier.

Step 4: Calculate the Compressed Air Demand of Air Jet Loom Workshop

It should be calculated as follows

Qg=QzN(1+Kz)

Qg: the air supply volume of the air compressor station (m3/min);

Qz: the compressed air consumption of each loom (m3/min);

N : the number of air-jet looms;

Kz: the leakage rate of the pipeline system (generally 0.2 ~ 0.4) .

Step 5: Determination of Air Compressor Supply Pressure

The air supply pressure of the air compressor is very important to ensure the working efficiency of the air-jet loom, save energy and prolong the service life of the air compressor.

The air supply pressure of the air compressor can be calculated as follows:

Pg=(Pz+0.1)+PR

Pg: the air supply pressure of the air compressor (MPa);

Pz: the working pressure of the loom (MPa) );

PR: pressure drop (MPa) pass pipes, dryers, filters, etc. (normally 0.05MPa ~ 0.10MPa).

Step 6: The Air Compressor Suitable for the Air Jet Loom

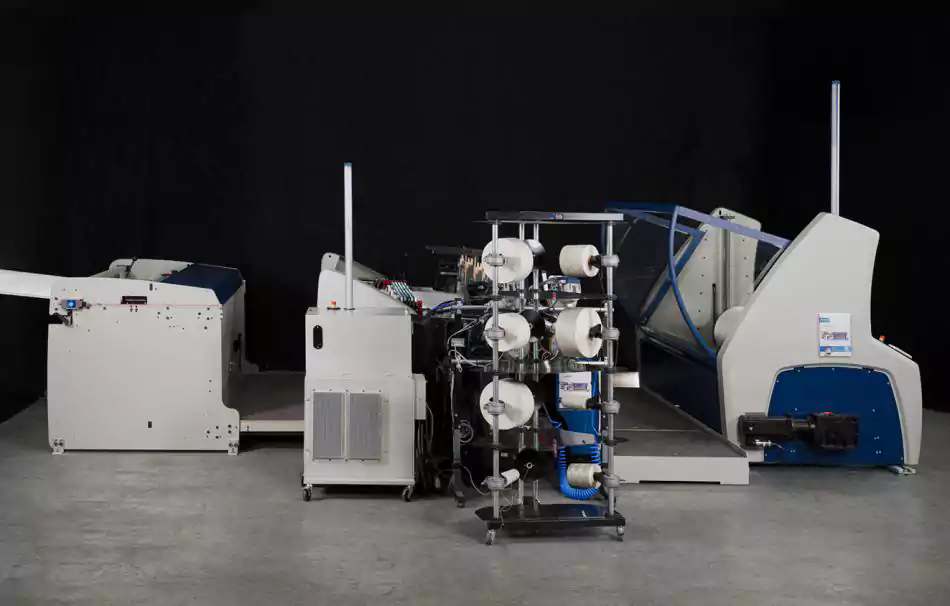

BD Low Pressure Rotary Screw Air Compressor

The BD Low Pressure Rotary Screw Air Compressor is an ideal choice for air jet looms. It features a durable airend, PM motor, oil separator, and inverter to provide reliable and efficient compressed air.